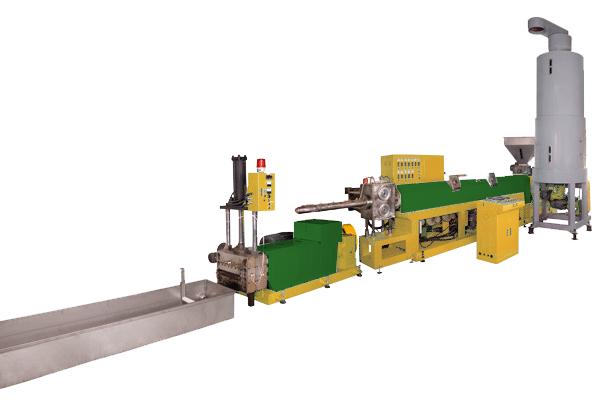

PS85, PS100

SPAGHETTI TYPE WATER COOLING RECYCLING MACHINE

Materials to be applied: PE, PP, PS, ABS, Film, Bottle, and Sheet.

- Crushing, extrusion and pelletizing three-in-one system can save space, reduce energy consumption, and lessen labor costs.

- Vent on the Barrel to evaporate the volatiles from the Recycle Material.

- Die Face water-cooling for easy operation.

- Conveyor material loader provides a safe working environment.

- The Vertical Centrifuges separate and dry the Pellets faster.

- Pressure gauge meter display to maintain good production and operator safety.

- Second extruder

- Magnetic Metal detector (Made in Germany),

- Water Cooling Tower

- Vacuum Pump, Chiller

- Non-Stop Screen Changer

- Vibratory Sorting Machine

- Nip Roll Device

| Model |

Max. Output |

Extruder Main Motor |

Sub-Extruder Motor |

Side-Feeding |

|---|

| PS85 |

200Kg/Hr |

60HP + AC Inverter |

25HP + AC Inverter |

7.5HP |

| PS100 |

350Kg/Hr |

100HP + AC Inverter |

40HP + AC Inverter |

10HP |

-

Specifications subject to change without notice.