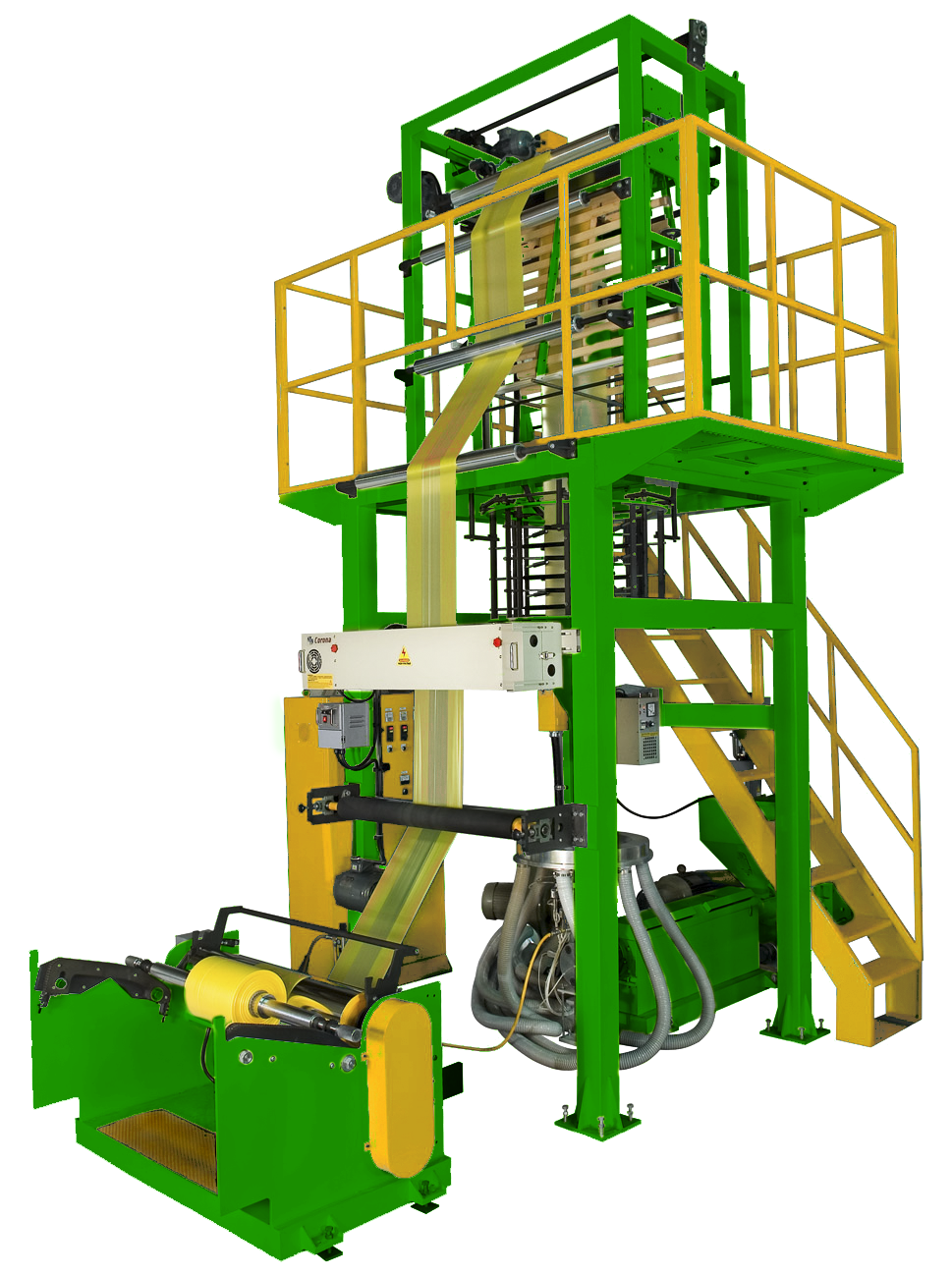

EB45T~EB65T

ECONOMIC MONO LAYER BLOWN FILM MACHINE

- Advanced Die and Screw Design for high output and reliable production quality.

- Inverter Drive for energy saving and convenient operation.

- Complete HDPE, LDPE and LLDPE Die, Air Ring and Screws to be chosen to fit different materials.

- An economical method for producing films.

- Simple construction with easy operation.

- Oscillating Haul Off

- Embossing roller

- Auto-loader

- Manual screen changer

- Dual Layer Die

- Surface treater

- Melt and temperature meter

- Auto surface winder upgrade

- Face-t-face rewing

- Rotary Die and Air Ring

- Edge guide

- Chiller air box.

| Model |

Suitable Material |

Screw Dia. |

Max. Film Width |

Max. Output |

Screw L/D Ratio |

Main Motor (w/inverter) |

|---|

| EB45T |

HDPE/LDPE/LLDPE/MDPE/EVA |

Ø45 |

700mm |

60Kg/Hr |

28:1 |

30HP |

| EB55T |

HDPE/LDPE/LLDPE/MDPE/EVA |

Ø55 |

900mm |

90Kg/Hr |

28:1 |

40HP |

| EB65T |

HDPE/LDPE/LLDPE/MDPE/EVA |

Ø65 |

1200mm |

150Kg/Hr |

28:1 |

60HP |

-

Specifications subject to change without notice.